The purpose of the International Aeronautical and Maritime Search and Rescue Manual for Mobile Facilities, which is intended for carriage aboard search and rescue units, and aboard civil aircraft and vessels, is to provide guidance to those who:

* operate aircraft, vessels or other craft, and who may be called upon to use the facility to support SAR operations

* may need to perform on-scene coordinator functions for multiple facilities in the vicinity of a distress situation

* experience actual or potential emergencies, and may require search and rescue (SAR) assistance.

Responsibilities and Obligations to Assist:

Under long-standing traditions of the sea and various provisions of international law, ship masters are obligated to assist others in distress at sea whenever they can safely do so.

The responsibilities to render assistance to a distressed vessel or aircraft are based on humanitarian considerations and established international practice. Specific obligations can be found in several conventions, including the following:

· Annex 12 to the Convention on International Civil Aviation

· International Convention on Maritime Search and Rescue

· Regulation V/1 0 of the International Convention for the Safety of Life at Sea, 1974 (SOLAS 1974). (See appendix A).

National and Regional SAR System Organization:

Many States have accepted the obligation to provide aeronautical and maritime SAR co-ordination and services on a 24-hour basis for their territories, territorial seas, and where appropriate, the high seas.

• To carry out these responsibilities, States have established national SAR organizations, or, joined one or more other States to form a regional SAR organization associated with an ocean area or continent.

• A search and rescue region (SRR) is an area of defined dimensions associated with a rescue co-ordination center (RCC) within which SAR services are provided.

1. SRRs help to define who has primary responsibility for coordinating responses to distress situations in every area of the world, but they are not intended to restrict anyone from assisting persons in distress

2. the International Civil Aviation Organization (ICAO) regional air navigation plans (RANPS) depict aeronautical SRRs 3. the International Maritime Organization (IMO) Global SAR Plan depicts maritime SRRS.

Search and Rescue Region (SRR) and its purpose:

A Search and Rescue Region (SRR) is an area of defined dimensions associated with a rescue co-ordination centre (RCC) within which SAR services are provided.

Purpose:-

- SRRs help to define who has primary responsibility for co-ordinating responses to distress situations in every area of the world, but they are not intended to restrict anyone from assisting persons in distress.

- The International Civil Aviation Organization (ICAO) regional air navigation plans (RANPs) depict aeronautical SRRs.

- The International Maritime Organization (IMO) Global SAR Plan depicts maritime SRRs.

SAR co-ordination to be carried out on the scene of distress in search and Rescue operation:

SAR Co-ordination:

The SAR system has three general levels of co-ordination:

- SAR co-ordinators (SCs)

- SAR mission co-ordinators (SMCs)

- On-scene co-ordinators (OSCs).

- SAR Co-ordinators:

- SCs are the top level SAR managers; each State normally will have one or more persons or agencies for whom this designation may be appropriate.

- SCs have the overall responsibility for:

- Establishing, staffing, equipping and managing the SAR system.

- Establishing RCCs and rescue sub-centres (RSCs).

- Providing or arranging for SAR facilities.

- Co-ordinating SAR training.

- Developing SAR policies.

- SAR Mission Co-ordinator:

- Each SAR operation is carried out under the guidance of an SMC. This function exists only for the duration of a specific SAR incident and is normally performed by the RCC chief or a designee. The SMC may have assisting staff.

- The SMC guides a SAR operation until a rescue has been effected or it becomes apparent that further efforts would be of no avail.

- The SMC should be well trained in all SAR processes, be thoroughly familiar with the applicable SAR plans, and:

- Gather information about distress situations.

- Develop accurate and workable SAR action plans.

- Dispatch and co-ordinate the resources to carry out SAR missions.

- SMC duties include:

- obtain and evaluate all data on the emergency

- ascertain the type of emergency equipment carried by the missing or distressed craft

- remain informed of prevailing environmental conditions

- if necessary, ascertain movements and locations of vessels and alert shipping in likely search areas for rescue, lookout and/or radio watch

- plot the areas to search and decide on methods and facilities to be used

- develop the search action plan and rescue action plan as appropriate

- co-ordinate the operation with adjacent RCCs when appropriate

- arrange briefing and debriefing of SAR personnel

- evaluate all reports and modify search action plan as necessary

- arrange for refuelling of aircraft and, for prolonged search, make arrangements for the accommodation of SAR personnel

- arrange for delivery of supplies to sustain survivors

- maintain in chronological order an accurate and up-to-date record

- issue progress reports

- determine when to suspend or terminate the search

- release SAR facilities when assistance is no longer required

- notify accident investigation authorities

- if applicable, notify the State of registry of the aircraft

- prepare a final report.

- On-Scene Co-ordinator:

- When two or more SAR facilities are working together on the same mission, one person on-scene may be needed to co-ordinate the activities of all participating facilities.

- The SMC designates an OSC, who may be the person in charge of a:

- Search and rescue unit (SRU), ship, or aircraft participating in a search, or

- Nearby facility in a position to handle OSC duties.

- The person in charge of the first facility to arrive at the scene will normally assume the OSC function until the SMC arranges for that person to be relieved.

- When two or more SAR facilities are working together on the same mission, one person on-scene may be needed to co-ordinate the activities of all participating facilities.

Also Check out:-

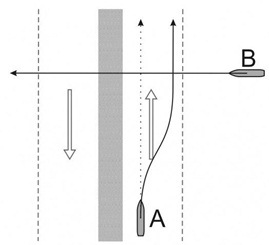

Man overboard preferred Manouevre