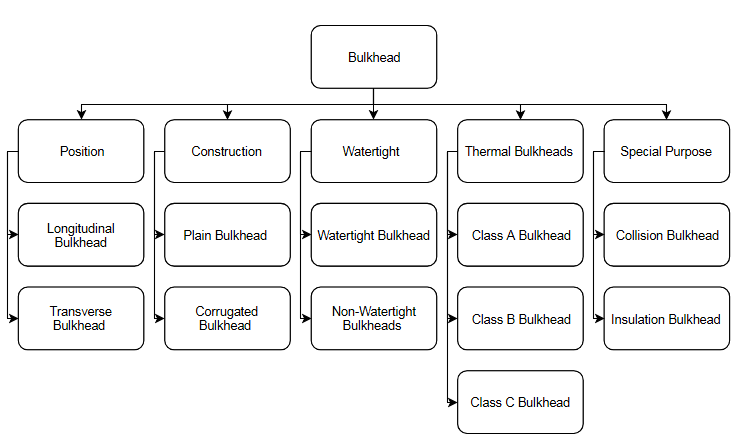

Types of Bulkheads:

Bulkheads:- Vertical partitions on a ship are called bulkheads.

Types of Bulkhead as per Orientation:

- Longitudinal: Placed in longitudinal direction on a ship.

- Transverse: placed in Transverse direction on a ship.

Types of Bulkheads as per construction:

- Watertight bulkheads: These bulkheads are water tight and prevent flooding. Numbers of Watertight bulkheads: 1- Collision bulkhead, 1- aft peak bulkhead, 1- Bulkhead of engine room and 1- bulkhead aft of engine room. Aft peak bulkhead and bulkhead aft of engine room may be combined into the additional bulkheads are to be provided as per rules depending upon the length of the ship & requirements.

- Non-watertight bulkheads:

- Are screens in accommodation and do not contribute to strength or water tightness.

- Used to subdivide compartment into smaller units of accommodation of stores Non-watertight Bulkheads.

- Non-watertight bulkheads perform supporting function.

- Its stiffeners have to be sufficient for the load carried.

- Corrugated bulkheads may be used.

- On-tight or tank bulkheads: Form boundary of oil tanks. Are oil tight in nature & are tested for the same.

-

Naval Architecture Solved MMD Past Papers Phase 2 Chief Mate₹53.00

Naval Architecture Solved MMD Past Papers Phase 2 Chief Mate₹53.00 -

2nd Mate (F.G.) & NCV (NWKO) – Volume 3 (Cargo)₹224.00

2nd Mate (F.G.) & NCV (NWKO) – Volume 3 (Cargo)₹224.00 -

Cargo Consolidated Notes for Phase 1 Chief Mate₹410.00

Cargo Consolidated Notes for Phase 1 Chief Mate₹410.00 -

Cargo Solved MMD Past Papers Phase 1 Chief Mate (Theory) till Dec’20₹229.00

Cargo Solved MMD Past Papers Phase 1 Chief Mate (Theory) till Dec’20₹229.00 -

Naval Architecture Class Notes Phase 2 Chief Mate by Gaurav Sama₹177.00

Naval Architecture Class Notes Phase 2 Chief Mate by Gaurav Sama₹177.00

Factors to be taken in to account during cargo planning stage in order to minimize the damage to watertight transverse bulkheads and tank tops in bulk carriers having combination cargo/ ballast holds.

The common damage/defects that may occur on watertight transverse bulkheads situated at the ends of dry cargo holds of a bulk carrier:-

- Fractures that may occur in the deck plating at hatches and in connected comings.

- Causes of cracking in way of no. 1 cargo hold.

The damages caused by cargoes in cargo holds, especially to tanktop plating and side:

- At loading and unloading ports for coal or iron ore, large grab buckets, high-capacity cargo.

- Loaders, bulldozers and pneumatic hammers may be employed for cargo-handling operations.

- Large grab buckets may cause considerable damage to tank top plating when being dropped to grab cargo.

- Use of bulldozers and pneumatic hammers may also be harmful to cargo hold structures and may result in damage to tank tops, bilge hoppers, hold frames and end brackets.

- Lumber cargoes may also cause damage to the cargo hold structures of smaller bulkers that are employed in the carriage of light bulk cargoes and lumbers.

- Cracking on large bulk carriers, Ballast tanks. Ability to interpret given figures for bending moments and shear forces.