Grain Securing Methods:-

Following are the recommended methods for securing grain as per International Grain Code to reduce Grain Heeling Moments on ship.

- Shifting boards (Filled/partly filled)

- Saucers (Filled)

- Bundling of bulk grain (Filled)

- Overstowing arrangements (Filled/partly filled)

- Strapping or lashing (Filled/partly filled)

- Feeders (Filled)

- Securing with wire mesh (Filled/partly filled)

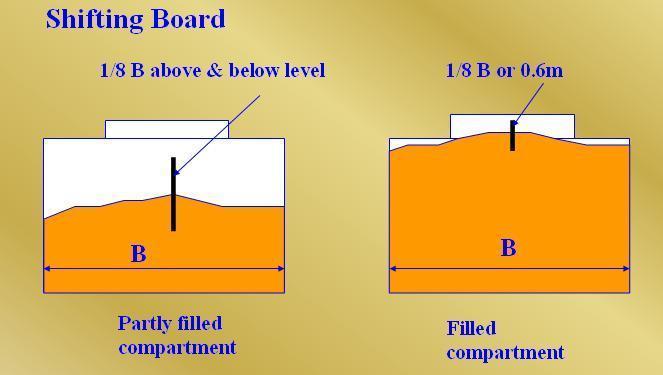

1) Shifting boards (Filled/partly filled)

- Longitudinal divisions (called shifting board), which must be grain tight may be fitted in both “filled” and “partly filled compartments”.

- In “filled compartments, they must extend downwards from the underside of the deck or hatchcovers, to a distance below the deckline of at least one-eighth the breadth of the compartment, or at least 0.6m below the surface of the grain after it has been assumed to shift through an angle of 15O.

- In a “partly filled compartment’, the division, should extend both above and below the level of grain, to a distance of one-eighth the breadth of the compartment.

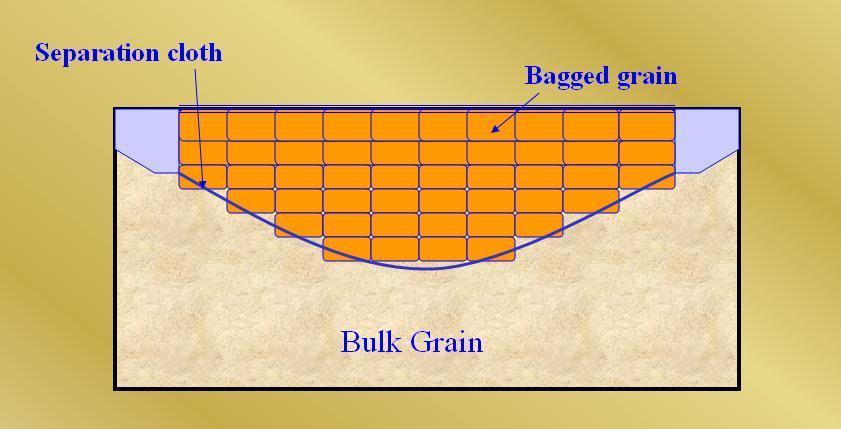

2) Saucers (Filled)

- For the purpose of reducing the heeling moment a saucer may be used in place of a longitudinal division in way of a hatch opening only in a filled, trimmed, compartment as defined in A 2.2, except in the case of linseed and other seeds having similar properties, where a saucer may not be substituted for a longitudinal division. If a longitudinal division is provided, it shall meet the requirements of A 10.9.

- The depth of the saucer, measured from the bottom of the saucer to the deck line, shall be as follows:

- For ships with a moulded breadth of up to 9.1 m, not less than 1.2 m.

- For ships with a moulded breadth of 18.3 m or more, not less than 1.8 m.

- For ships with a moulded breadth between 9.1 m and 18.3 m, the minimum depth of the saucer shall be calculated by interpolation.

- The top (mouth) of the saucer shall be formed by the underdeck structure in way of the hatchway, i.e. hatch side girders or coamings and hatch end beams. The saucer and hatchway above shall be completely filled with bagged grain or other suitable cargo laid down on a separation cloth or its equivalent and stowed tightly against adjacent structure so as to have a bearing contact with such structure to a depth equal to or greater than one half of the depth specified in A 14.2. If hull structure to provide such bearing surface is not available, the saucer shall be fixed in position by steel wire rope, chain, or double steel strapping as specified in A 17.1.4 and spaced not more than 2.4 m apart.

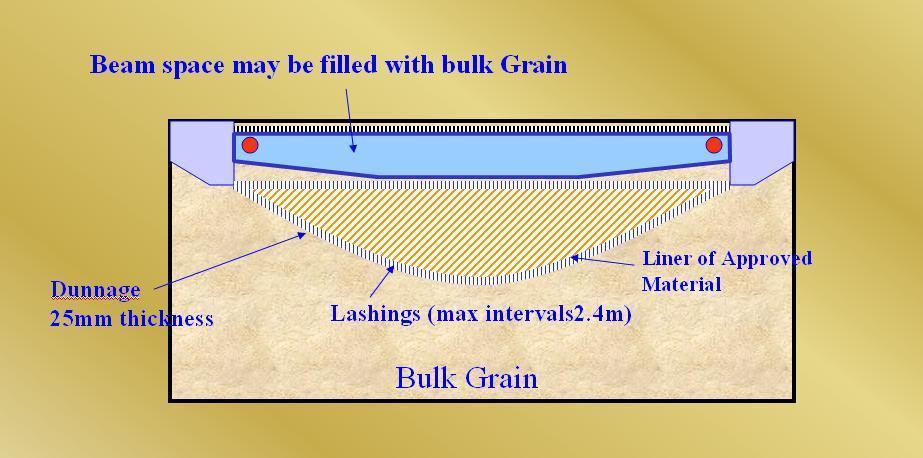

3) Bundling of bulk grain (Filled)

As an alternative to filling the saucer in a filled, trimmed, compartment with bagged grain or other suitable cargo a bundle of bulk grain may be used provided that:

- The dimensions and means for securing the bundle in place are the same as specified for a saucer in A 14.2 and A 14.3.

- The saucer is lined with a material acceptable to the Administration having a tensile strength of not less than 2,687 N per 5 cm strip and which is provided with suitable means for securing at the top.

- As an alternative to A 15.2, a material acceptable to the Administration having a tensile strength of not less than 1,344 N per 5 cm strip may be used if the saucer is constructed as follows:

3.1. Athwartship lashings acceptable to the Administration shall be placed inside the saucer formed in the bulk grain at intervals of not more than 2.4 m. These lashings shall be of sufficient length to permit being drawn up tight and secured at the top of the saucer.

3.2. Dunnage not less than 25 mm in thickness or other suitable material of equal strength and between 150 mm and 300 mm in width shall be placed fore and aft over these lashings to prevent the cutting or chafing of the material which shall be placed thereon to line the saucer.

- The saucer shall be filled with bulk grain and secured at the top except that when using material approved under A 15.3 further dunnage shall be laid on top after lapping the material before the saucer is secured by setting up the lashings.

- If more than one sheet of material is used to line the saucer they shall be joined at the bottom either by sewing or by a double lap.

- The top of the saucer shall be coincidental with the bottom of the beams when these are in place and suitable general cargo or bulk grain may be placed between the beams on top of the saucer.

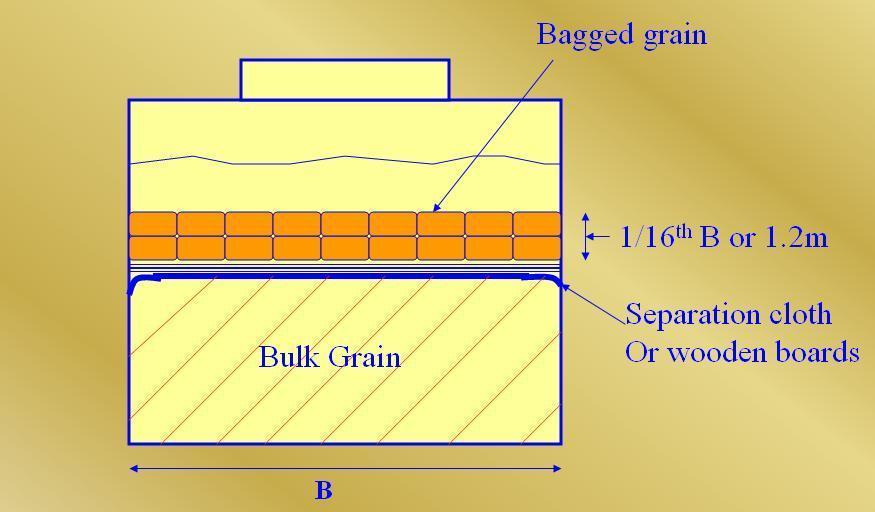

4) Overstowing arrangements (Filled/partly filled)

- Where bagged grain or other suitable cargo is utilized for the purpose of securing partly filled compartments, the free grain surface shall be level and shall be covered with a separation cloth or equivalent or by a suitable platform. Such platform shall consist of bearers spaced not more than 1.2 m apart and 25 mm boards laid thereon spaced not more than 100 mm apart. Platforms may be constructed of other materials provided they are deemed by the Administration to be equivalent.

- The platform or separation cloth shall be topped off with bagged grain tightly stowed and extending to a height of not less than one sixteenth of the maximum breadth of the free grain surface or 1.2 m, whichever is the greater.

- The bagged grain shall be carried in sound bags which shall be well filled and securely closed.

- Instead of bagged grain, other suitable cargo tightly stowed and exerting at least the same pressure as bagged grain stowed in accordance with A 16.2 may be used.

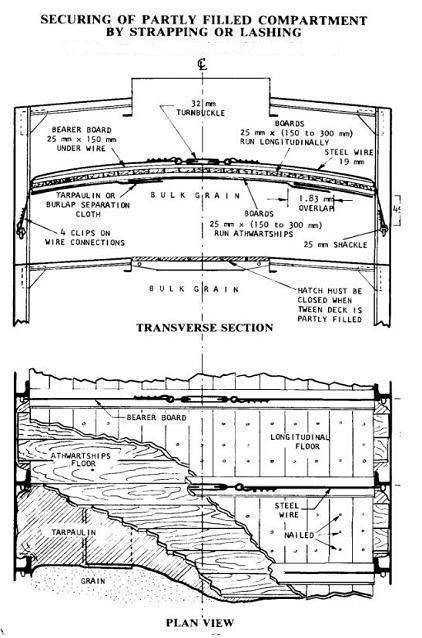

5) Strapping or lashing (Filled/partly filled)

When, in order to eliminate heeling moments in partly filled compartments, strapping or lashing is utilized, the securing shall be accomplished as follows:

- The grain shall be trimmed and levelled to the extent that it is very slightly crowned and covered with burlap separation cloths, tarpaulins or the equivalent.

- The separation cloths and/or tarpaulins shall overlap by at least 1.8 m.

- Two solid floors of rough 25 mm x 150 mm to 300 mm lumber shall be laid with the top floor running longitudinally and nailed to an athwartships bottom floor. Alternatively, one solid floor of 50 mm lumber, running longitudinally and nailed over the top of a 50 mm bottom bearer not less than 150 mm wide, may be used. The bottom bearers shall extend the full breadth of the compartment and shall be spaced not more than 2.4 m apart. Arrangements utilizing other materials and deemed by the Administration to be equivalent to the foregoing may be accepted.

- Steel wire rope (19 mm diameter or equivalent), double steel strapping (50 mm x 1.3 mm and having a breaking load of at least 49 kN), or chain of equivalent strength, each of which shall be set tightly by means of a 32 mm turnbuckle, may be used for lashings. A winch tightener, used in conjunction with a locking arm, may be substituted for the 32 mm turnbuckle when steel strapping is used, provided suitable wrenches are available for setting up as necessary. When steel strapping is used, not less than three crimp seals shall be used for securing the ends. When wire is used, not less than four clips shall be used for forming eyes in the lashings.

- Prior to the completion of loading the lashing shall be positively attached to the framing at a point approximately 450 mm below the anticipated final grain surface by means of either a 25 mm shackle or beam clamp of equivalent strength.

- The lashings shall be spaced not more than 2.4 m apart and each shall be supported by a bearer nailed over the top of the fore and aft floor. This bearer shall consist of lumber of not less than 25 mm x 150 mm or its equivalent and shall extend the full breadth of the compartment.

- During the voyage the strapping shall be regularly inspected and set up where necessary.

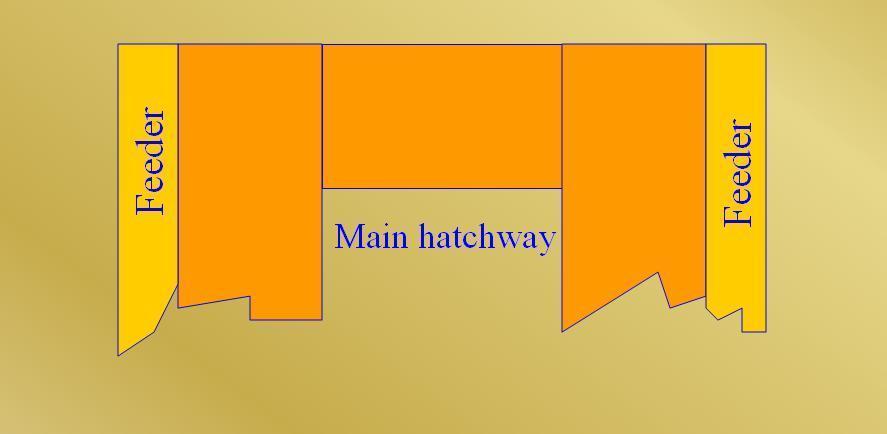

6) Feeders (Filled)

- It may be assumed that under the influence of ship motion underdeck voids will be substantially filled by the flow of grain from a pair of longitudinal feeders provided that:

- Bullet the feeders extends for the full length of the deck and that the perforations therein are adequately spaced.

- Bullet the volume of each feeder is equal to the volume of the underdeck void outboard of the hatchside girder and its continuation.

7) Securing with wire mesh (Filled/partly filled)

When, in order to eliminate grain heeling moments in partly filled compartments, strapping or lashing is utilized, the securing may, as an alternative to the method described in A 17, be accomplished as follows:

- The grain shall be trimmed and levelled to the extent that it is very slightly crowned along the fore and aft centreline of the compartment.

- The entire surface of the grain shall be covered with burlap separation cloths, tarpaulins, or the equivalent. The covering material shall have a tensile strength of not less than 1,344 N per 5 cm strip.

- Two layers of wire reinforcement mesh shall be laid on top of the burlap or other covering. The bottom layer is to be laid athwartships and the top layer is to be laid longitudinally. The lengths of wire mesh are to be overlapped at least 75 mm. The top layer of mesh is to be positioned over the bottom layer in such a manner that the squares formed by the alternate layers measure approximately 75 mm x 75 mm. The wire reinforcement mesh is the type used in reinforced concrete construction. It is fabricated of 3 mm diameter steel wire having a breaking strength of not less than 52 kN/cm2 welded in 150 mm x 150 mm squares. Wire mesh having mill scale may be used but mesh having loose, flaking rust may not be used.

- The boundaries of the wire mesh, at the port and starboard side of the compartment, shall be retained by wood planks 150 mm x 50 mm.

- Hold-down lashings, running from side to side across the compartment, shall be spaced not more than 2.4 m apart except that the first and the last lashing shall not be more than 300 mm from the forward or after bulkhead, respectively. Prior to the completion of the loading, each lashing shall be positively attached to the framing at a point approximately 450 mm below the anticipated final grain surface by means of either a 25 mm shackle or beam clamp of equivalent strength. The lashing shall be led from this point over the top of the boundary plank described in A 18.1.4, which has the function of distributing the downward pressure exerted by the lashing. Two layers of 150 mm x 25 mm planks shall be laid athwartships centred beneath each lashing and extending the full breadth of the compartment.

- The hold-down lashings shall consist of steel wire rope (19 mm diameter or equivalent), double steel strapping (50 mm x 1.3 mm and having a breaking load of at least 49 kN), or chain of equivalent strength, each of which shall be set tight by means of a 32 mm turnbuckle. A winch tightener, used in conjunction with a locking arm, may be substituted for the 32 mm turnbuckle when steel strapping is used, provided suitable wrenches are available for setting up as necessary. When steel strapping is used, not less than three crimp seals shall be used for securing the ends. When wire rope is used, not less than four clips shall be used for forming eyes in the lashings.

- During the voyage the hold-down lashings shall be regularly inspected and set up where necessary.

Code of Safe Practice for Carriage of Grain:

- SOLAS regulation VI/9.1 (Requirements for cargo ships carrying grain) provides that a cargo ship carrying grain must hold a Document of Authorization as required by the “International Grain Code”, and for the purposes of regulation 9, the requirements of the Code should be treated as mandatory. A ship without a Document of Authorization must not load grain until the master satisfies the flag State Administration, or the SOLAS Contracting Government of the port of loading on behalf of the Administration, that the ship will comply with the requirements of the International Grain Code in its proposed loaded condition (regulation 9.2).

- The International Code for the Safe Carriage of Grain in Bulk is commonly called the “International Grain Code” was adopted by the IMO Maritime Safety Committee by resolution MSC.23(59). It applies to ships regardless of size, including those of less than 500gt, engaged in the carriage of grain in bulk, to which part C of chapter VI of the 1974 SOLAS Convention, as amended, applies (A 1.1).

- Grain Code defines “grain” as including wheat, maize (corn), oats, rye, barley, rice, pulses, seeds and processed forms thereof, whose behaviour is similar to that of grain in its natural state .

- A Document of Authorization must be issued by or on behalf of the flag State Administration for every ship loaded in accordance with the Code, and must be accepted as evidence that the ship is capable of complying with the Code (A 3.1).

- The Document of Authorization must accompany or be incorporated into the Grain Loading Manual provided to enable the master to meet the requirements of A 7 (A 3.2). The Manual must meet the requirements of A 6.3 (A 3.2).

- The Document of Authorization, grain loading stability data and associated plans may be in the official language or languages of the issuing country. If the language used is neither English nor French, the text must include a translation into either English or French.

- A copy of the Document of Authorization, grain loading stability data and associated plans must be placed on board so that the master, if required, may produce them for inspection by the SOLAS Contracting Government at the loading port (A 3.4).

- The flag State Administration, or a SOLAS Contracting Government on its behalf, may exempt individual ships or classes of ship from particular requirements of the Code if it considers that the sheltered nature and conditions of the voyage are such as to render their application unreasonable or unnecessary.

- Information in printed booklet form (i.e. a Grain Loading Manual) must be provided to enable the master to ensure that the ship complies with the Code when carrying grain in bulk on an international voyage (A 6.1). Information to be in the booklet is listed in A 6.2 and A 6.3. The information in A 6.2 must be acceptable to the flag State Administration (or a Contracting Government on its behalf), while the information in A 6.3 must be approved by that body.

- A ship not having on board a Document of Authorisation issued in accordance with A 3 of the Code may be permitted to load bulk grain subject to certain conditions, one of which is that the total weight of the bulk grain does not exceed one third of the ship’s deadweight (A 9.1).

Stability Criteria for Ships with DOA:-

- A document of authorization shall be issued for every ship loaded in accordance with the regulations of this Code either by the Administration or an organization recognized by it or by a Contracting Government on behalf of the Administration. It shall be accepted as evidence that the ship is capable of complying with the requirements of these regulations.

- The document shall accompany or be incorporated into the grain loading manual provided to enable the master to meet the requirements of A7. The manual shall meet the requirements of A6.3.

- Such a document, grain loading stability data and associated plans may be drawn up in the official language of languages of the issuing country. If the language used is neither English nor French, the text shall include a translation into one of these languages.

- A copy of such a document, grain loading stability data and associated plans shall be placed on board in order that master, if so required, shall produce them for the inspection of the Contracting Government of the country of the port of loading.

- A ship without such a document of authorization shall not load grain until the master demonstrates to the satisfaction of the Administration, or of the Contracting Government of the port of loading acting on behalf of the Administration, that, in its loaded condition for the intended voyage, the ship complies with the requirements of this Code.

- EQUIVALENTS:- Where an equivalent accepted by the Administration in accordance with regulation I/5 of the International Convention for the Safety of Life at Sea, 1974, as amended, is used, particulars shall be included in the document of authorization or in the grain loading manual.

- EXEMPTIONS FOR CERTAIN VOYAGES:- The Administration, or a Contracting Government on behalf of the Administrations, may, if it considers that the sheltered nature and conditions of the voyage are such as to render the application of any of the requirements of this Code unreasonable or unnecessary, exempt from particular requirements individual ships or classes of ships.

- INFORMATION REGARDING SHIP’S STABILITY AND GRAIN LOADING:-

- Ship’s particulars;

- Lightship displacement and the vertical distance from the intersection of the moulded base line and midship section to the center of gravity (KG).

- Table of liquid free surface corrections;

- Capacities and centers of gravity;

- Curve or table of angle of flooding, where less than 40°, at all permissible displacements;

- Curves or tables of hydrostatic properties suitable for the range of operating drafts; and

- Cross curves of stability which are sufficient for the purpose of the requirements in A7 and which include curves at 12° and 40°.

- Information which shall be approved by the Administration:-

- Curves or tables of volumes, vertical centers of volumes, and assumed volumetric heeling moments for every compartment, filled or partly filled, or combination thereof, including the effects of temporary fittings;

- Tables or curves of maximum permissible heeling moments for varying displacements and varying vertical center of gravity to allow the master to demonstrate compliance with the requirement.

- This requirement shall apply only to ships the keels of which are laid on or after the entry into force of this Code.

- Details of the scantlings of any temporary fittings.

- Loading instructions in the form of notes summarizing the requirements of this Code.

- Typical loaded service departure and arrival conditions and where necessary intermediate worst service conditions*.

Stability Criteria for ships without DOA:

- Total weight of the bulk grain shall not exceed one third of the deadweight of the ship.

- All “filled compartments, trimmed” shall be fitted with centreline divisions extending, for the full length of such compartments, downwards from the underside of the deck or hatch covers to a distance below the deck line of at least one eighth of the maximum breadth of the compartment or 2.4 m whichever is the greater except that saucers constructed in accordance with A 14 of code may be accepted in lieu of a centreline division in and beneath a hatchway except in the case of linseed and other seeds having similar properties.

- All hatches to “filled compartments, trimmed” shall be closed and covers secured in place.

- All free grain surfaces in partly filled cargo space shall be trimmed level and secured in accordance with A 16, A 17 or A 18 of code.

- Throughout the voyage the metacentric height after correction for the free surface effects of liquids in tanks shall be 0.3 m.

- The master demonstrates to the satisfaction of the Administration or the Contracting Government of the port of loading on behalf of the Administration that the ship in its proposed loaded condition will comply with the requirements of this section.

Grain Loading Stability Booklet:

- Grain stability booklet help us determine the volumetric heeling moment due to grain shift, which we compare against the allowable heeling moment and we can find the heel angle and the the residual dynamical stability which should be less than 12O and 0.075m*rad.

- But the actual intact stability of the ship is calculated with the stability booklet.

- Basically it is provided to calculate the heeling moment due to grain, which is a major hazard.

- Contents:-

- Instruction to the master

- Main particulars

- Definitions and conversion table

- Notes regarding grain stability calculation

- Stability in general

- Definition on grain

- Grain heeling moments

- Max. Allowable heeling moments

- Working example

- How to check the stability of the vessel

- Tank and capacity information

- Loading conditions

- Grain shifting moments for cargo holds

- Max. Allowable grain heeling moment

- Extra calculation sheets

Basic principles of Safe Stowage & Securing of Cargoes:

- Improper stowage and securing of cargo is potentially hazardous to other cargoes as well as to the ship itself. Hence, all cargoes must be stowed in such a way that the ship and persons on board are not put at risk.

- Proper planning, execution and supervision are required for the safe stowage and securing of cargoes.

- Persons responsible for planning and supervision must have sound practical knowledge and be familiar with the contents of Cargo Securing Manual and its application.

- The stowage and securing of cargo must be done taking into account the most severe weather conditions expected from available data and past experience on the voyage.

- Ship-handling decisions by the Master regarding course and speed in bad weather should take into account the type and stowage position of the cargo and the securing arrangements.

Procedures for Preparation of Cargo holds for Carriage of Grain:

One of the most difficult and dangerous cargoes to carry in bulk are grain cargoes. Most grains have an angle of repose (slip angle) of about 20° from the horizontal, which means that if the ship rolls more than 20° the cargo will shift. Then this happens the ship will develop a large list, lying on her side and still rolling will obviously cause a greater shift of cargo which in turn will capsize the vessel.

Most authorities therefore request that the master proves that his ship is capable of remaining stable even if the grain cargo shifts. This is done by the compiling of the Grain Loading Form which fully outlines the ships stability at the worse condition on passage.

Because grain cargoes are liable to shift, heavy emphasis is placed on the stability of ships that carry them. The main reason is the variation in the types of grain, including its size and its ability to develop a free flow state when loaded in bulk. Each ship carrying grain has to provide grain specific stability information, including grain heeling moments, to the terminal. This section looks at various problems, methods and precautions that must be taken when carrying grain cargoes. Grain cargoes carried in bags are not considered as bulk cargo.

The bulk carriers’ grain loading manual contains Volumetric Heeling Moments (VHM), which are values based on an assumed surface grain shift of 15° (for a full compartment) and 25° (for a partially full compartment).

1. To avoid shifting of cargo, the grain surfaces must be reasonably trimmed:

- Filled compartment, trimmed the cargo should be trimmed so that all spaces under deck and hatch covers are filled to the fullest extent possible.

- Filled compartment, untrimmed the cargo should be trimmed within the hatchway but may be left at its natural angle of repose on the surrounding area of the hatchway. The same can be applied for a filled compartment, trimmed if:

- dispensation is granted from trimming by the authority issuing the Document of Authorisation on the basis that the cargo can flow freely to underdeck empty areas through feeder ducts, perforated decks, etc, or

- The compartment is designated a `Specially Suitable Compartment’, in which case exemption may be granted from trimming the compartment ends.

2. If the cargo is stowed only in the lower compartment, the lower compartment hatch covers should be secured in the approved manner.

3. If the cargo is stowed in the upper compartment above a tween deck whose covers are not grain- tight, the covers should be made grain-tight using sealing tape, tarpaulins or separation cloths.

4. In partly filled compartments, the surface of bulk grain should be secured by over-stowing except in cases where heeling moments due to grain shift have been calculated and taken into consideration for stability of the vessel.

5. Longitudinal divisions may be fitted to reduce heeling moments due to shift of grain in filled compartments, trimmed, filled compartments, untrimmed and partly filled compartments, provided that each division:

a. Is made grain-tight.

b. Is constructed according to the Grain Code standards.

c. Extends from deck to deck in tweendecks.

d. Extends downwards from the underside of the hatch covers.

6. The Master shall ensure that the ship:

a. Before loading, can comply with intact stability criteria at all stages of the voyage.

b. Is upright before proceeding to sea.

c. Has all the paperwork completed and onboard.

Fumigation requirement:-

Charterers and shippers may require the cargo to be fumigated. If this is to be done during the voyage or before or after loading, full and clear instructions should be received from the charterers and shippers. These instructions should refer to product data sheets and the correct procedures and safety advice, application dangers, method of handling, and requirements for personal protective equipment and monitoring equipment. Refer to IMO Recommendations on the Safe Use of Pesticides on Ships. Always carry out a risk assessment.

A qualified fumigator should be engaged by the charterers when fumigation is to be done in port.

All spaces should be padlocked and sealed to prevent anyone from entering the space. No-one should enter a space that has been fumigated until after it has been thoroughly ventilated. It is recommended that an expert chemist declares whether the space is safe to enter. If the cargo requires ventilation after fumigation, advice should be sought from fumigation experts in respect to crew safety.

Fuel oil tanks precautions:-

- Masters and officers must be aware of the location of the heated fuel oil tanks.

- Masters and officers should monitor the tank top temperature above the fuel oil tanks as this can affect the integrity of certain cargoes – particularly grain cargoes.

- Fuel oil temperatures can be monitored on the fuel oil transfer pumps.

- Masters and chief engineers should manage the fuel oil onboard to reduce heat damage to cargoes loaded in holds above heated fuel oil tanks.

- Heat only fuel oil tanks in use.

Grain Code:- Strength of Grain Fittings:

- Timber:- All timber used for grain fittings shall be of good sound quality and of a type and grade which has been proved to be satisfactory for this purpose. The actual finished dimensions of the timber shall be in accordance with the dimensions specified below. Plywood of an exterior type bonded with waterproof glue and fitted so that the direction of the grain in the face plies is perpendicular to the supporting uprights or binder may be used provided that its strength is equivalent to that of solid timber of the appropriate scantlings.

- Working stresses:- When calculating the dimensions of divisions loaded on one side, using tables A 13-1 to A 13-6, the following working stresses should be adopted:

For divisions of steel: 19.6 kN/cm2

For divisions of wood: 1.57 kN/cm2

(1 newton is equivalent to 0.102 kilograms).

- Other materials:- Materials other than wood or steel may be approved for such divisions provided that proper regard has been paid to their mechanical properties.

- Uprights:-

- Unless means are provided to prevent the ends of uprights being dislodged from their sockets, the depth of housing at each end of each upright shall be not less than 75 mm. If an upright is not secured at the top, the uppermost shore or stay shall be fitted as near thereto as is practicable.

- The arrangements provided for inserting shifting boards by removing a part of the cross-section of an upright shall be such that the local level of stresses is not unduly high.

- The maximum bending moment imposed upon an upright supporting a division loaded on one side shall normally be calculated assuming that the ends of the uprights are freely supported. However, if an Administration is satisfied that any degree of fixity assumed will be achieved in practice, account may be taken of any reduction in the maximum bending moment arising from any degree of fixity provided at the ends of the upright.

- Composite section:- Where uprights, binders or any other strength members are formed by two separate sections, one fitted on each side of a division and interconnected by through bolts at adequate spacing, the effective section modulus shall be taken as the sum of the two moduli of the separate sections.

- Partial division:- Where divisions do not extend to the full depth of the cargo space such divisions and their uprights shall be supported or stayed so as to be as efficient as those which do extend to the full depth of the cargo space.

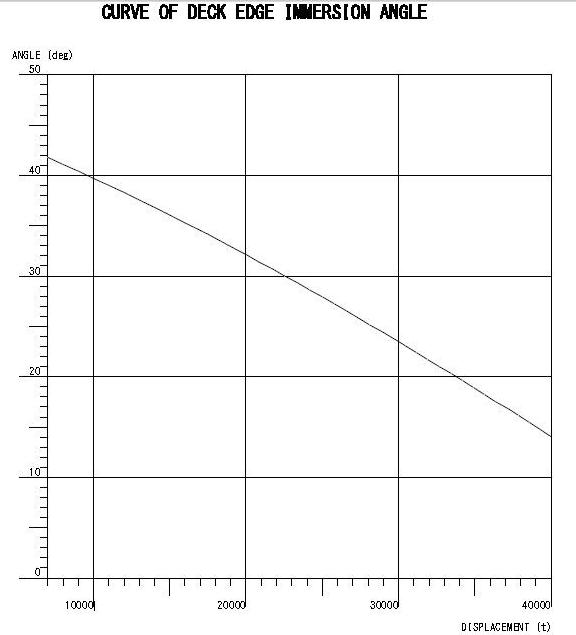

Grain Code:- Angle of flooding:

The term Angle of flooding means the angle of heel at which openings in the hull, superstructures or deckhouses, which cannot be closed weathertight, immerse. In applying this definition, small openings through which progressive flooding cannot take place need not be considered as open.

Grain Code:- Specially suitable compartment:

The term specially suitable compartment refers to a cargo space which is constructed with at least two vertical or sloping, longitudinal, grain-tight divisions which are coincident with the hatch side girders or are so positioned as to limit the effect of any transverse shift of grain. If sloping, the divisions shall have an inclination of not less than 30° to the horizontal.

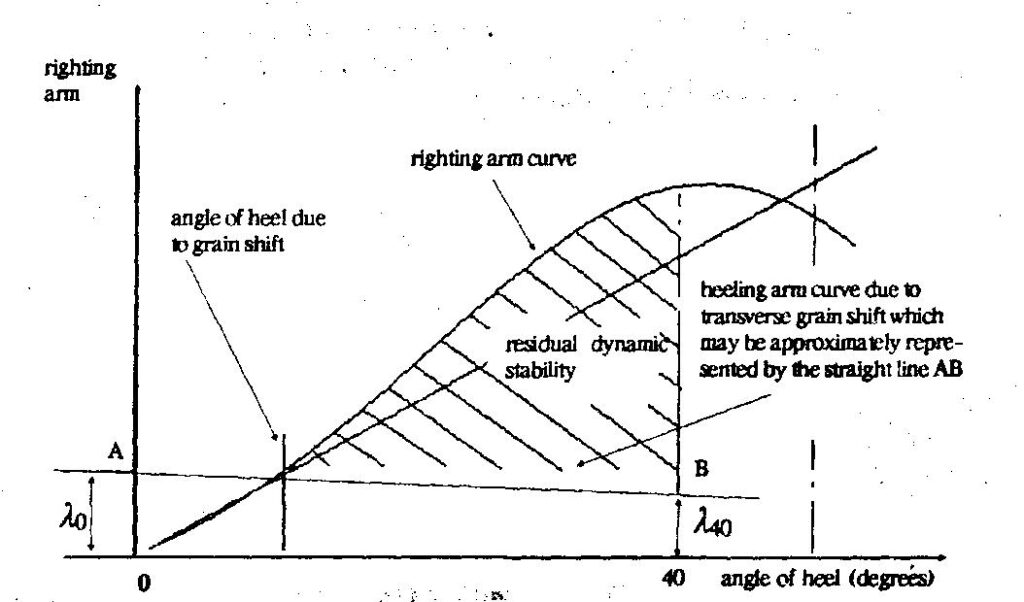

Grain Code:- Intact Stability & Securing of Grain Surface:

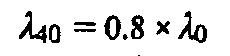

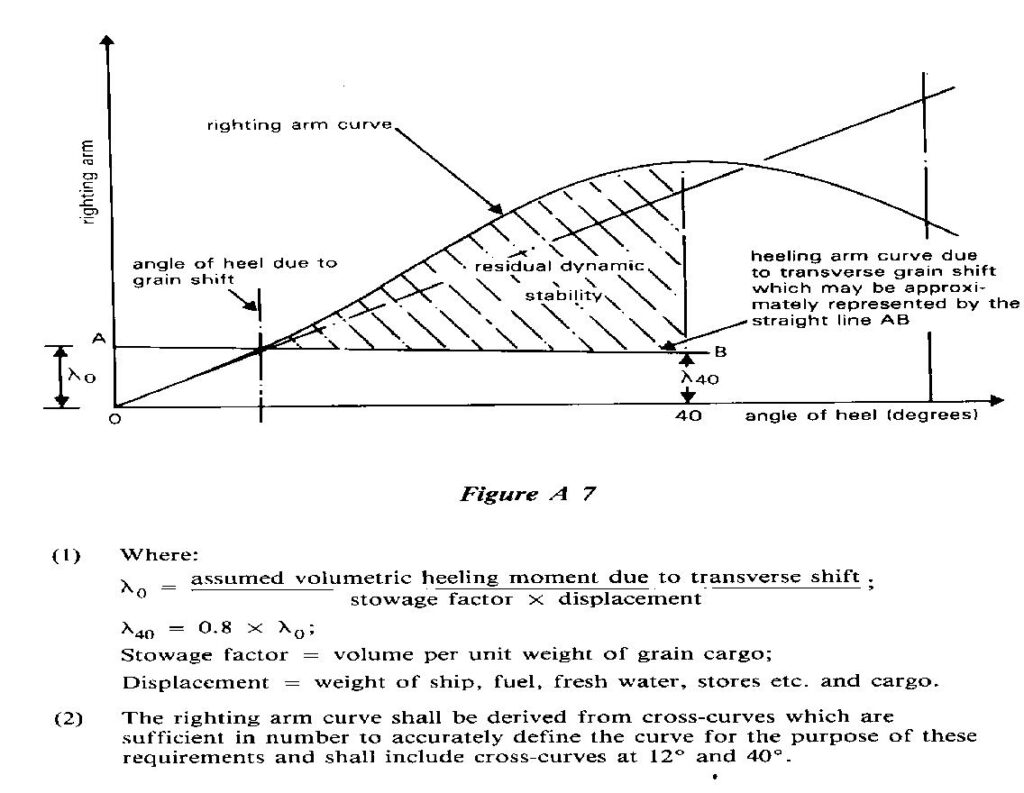

The intact stability characteristics of any ship carrying bulk grain shall be shown to meet, throughout the voyage, at least the following criteria after taking into account in the manner described in part B of this Code and, in figure A7, the heeling moments due to grain shift:

Figure A7

(1) Where:

Stowage factor – volume per unit weight of grain cargo; Displacement = weight of ship, fuel, fresh water, stores etc. and cargo.

(2) The righting arm curve shall be derived from cross curves which are sufficient in number to accurately define the curve for the purpose of these requirements and shall include cross-curves at 12° and 40°.

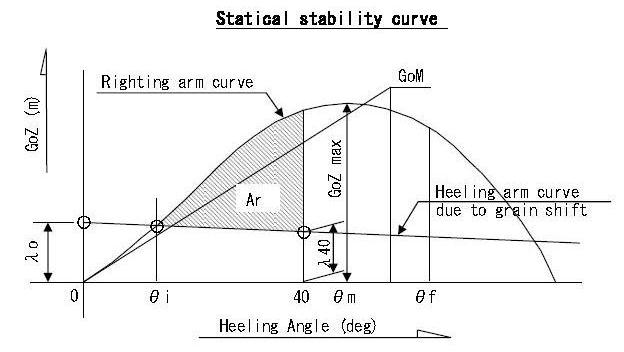

a) The angle of heel due to the shift of grain shall not be greater than 12° or in the case of ships constructed on or after 1 January 1994 the angle at which the deck edge is immersed, whichever is the lesser.

b) In the statical stability diagram, the net or residual area between the heeling arm curve and the righting arm curve up to the angle of heel of maximum difference between the ordinates of the two curves, or 40° or the angle of flooding (θ1), whichever is the least, shall in all conditions of loading be not less than 0.075 metre-radians; and

c) The initial metacentric height, after correction for the free surface effects of liquids in tanks, shall be not less than 0.30 m.

Before loading bulk grain the master shall, if so required by the Contracting Government of the country of the port of loading, demonstrate the ability of the ship at all stages of any voyage to comply with the stability criteria required by this section.

After loading, the master shall ensure that the ship is upright before proceeding to sea.

STABILITY REQUIREMENTS FOR EXISTING SHIPS:-

- For the purposes of this section the term “existing ship” means a ship, the keel of which is laid before 1 January 1994.

- An existing ship loaded in accordance with documents previously approved under regulation 12 of chapter VI of SOLAS 1960, IMO resolutions A. 184(VI) or A.264(VIII) shall be considered to have intact stability characteristics at least equivalent to the requirements of A7 of this Code. Documents of authorization permitting such loadings shall be accepted for the purposes of A7.2.

- Existing ships not having on board a document of authorization issued in accordance with A3 of this Code may apply the provisions of A9 without limitation of the deadweight which may be used for the carriage of bulk grain.

Permissible heeling moment of grain / Allowable Heeling Moment:-

The allowable heeling moment shows the maximum to be sufficient to comply with the “International Grain Code”:

This table shows the allowable maximum heeling moment due to shift of grain which satisfy following conditions:-

1) The angle of heel due to the shift of grain (θi) shall be not greater than 12 degrees. or the angle at which the deck edge is immersed, whichever is the lesser.

2) The net or residual area (Ar) between the heeling arm curve and righting arm curve up to angle of heel of maximum difference between the ordinates of the two curves (θm), or 40 degrees or the angle of flooding (θf), whichever is the least, shall be not less than 0.075 meterradians.

3) The initial metacentric height after correction for the free surface effects of liquids in tanks (GoM) shall be not less than 0.30 meters.

4) Ship should be upright on completion.

5) The master must demonstrate compliance with the criteria at all stage of the voyage.

HOW TO USE:- The allowable heeling moment on the condition is calculation as follows.

[ EXAMPLE ]

SHIP’S CONDITION : 11-1 GRAIN LOAD.COND.(DEP)TRIM

DISPLACEMENT (T) …. 36855.0

K M (m) …………. 11.32

K G (m) …………. 8.24

GGo (m) …………. 0.20

KGo (m) …………. 8.44

GoM (m) …………. 2.88

| DISPT. (t) | KGo | KGo | KGo |

| 8.40 m | 8.50 m | 8.44 m | |

| 36500.0 | 24531.0 | 23723.0 | 24207.8 |

| 37000.0 | 24865.0 | 24047.0 | 24537.8 |

| 36855.0 | 24768.1 | 23953.0 | 24442.1 |

ALLOWABLE HEELING MOMENT (T-M) ……. 24442

Stability Requirements:

- The intact stability characteristics of any ship carrying bulk grain shall be shown to meet, throughout the voyage, at least the following criteria after taking into account in the manner described in part B of this Code and, in figureA 7, the heeling moments due to grain shift:

- the angle of heel due to the shift of grain shall not be greater than 12° or in the case of ships constructed on or after 1 January 1994 the angle at which the deck edge is immersed, whichever is the lesser;

- in the statical stability diagram, the net or residual area between the heeling arm curve and the righting arm curve up to the angle of heel of maximum difference between the ordinates of the two curves, or 40° or the angle of flooding (01)’ whichever is the least, shall in all conditions of loading be not less than 0.075 metreradians; and

- the initial metacentric height, after correction for the free surface effects of liquids in tanks, shall be not less than 0.30 m.

- Before loading bulk grain the master shall, if so required by the Contracting Government of the country of the port of loading, demonstrate the ability of the ship at all stages of any voyage to comply with the stability criteria required by this section.

- After loading, the master shall ensure that the ship is upright before proceeding to sea.

Stability requirements for existing ships:-

- For the purposes of this section the term existing ship means a ship, the keel of which is laid before 25 May 1980.

- An existing ship loaded in accordance with documents previously approved under regulation 12 of chapter VI of SOLAS 1960, IMO resolutions A.184(VI) or A.264(VIII) shall be considered to have intact stability characteristics at least equivalent to the requirements of A 7 of this Code. Documents of authorization permitting such loadings shall be accepted for the purposes of A 7.2.

- Existing ships not having on board a document of authorization issued in accordance with A 3 of this Code may apply the provisions of A 9 without limitation on the deadweight which may be used for the carriage of bulk grain.

-

2nd Mate (F.G.) & NCV (NWKO) – Volume 3 (Cargo)₹ 219.00

2nd Mate (F.G.) & NCV (NWKO) – Volume 3 (Cargo)₹ 219.00 -

Cargo Consolidated Notes for Phase 1 Chief Mate₹ 361.00

Cargo Consolidated Notes for Phase 1 Chief Mate₹ 361.00 -

Cargo Solved MMD Past Papers Phase 1 Chief MatePrice range: ₹ 244.00 through ₹ 576.00

Cargo Solved MMD Past Papers Phase 1 Chief MatePrice range: ₹ 244.00 through ₹ 576.00

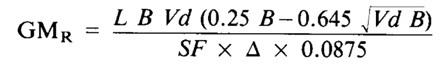

Loading Process for the vessels without Document of Authorization:

Ans:- Stability requirements for ships without documents of authorization carrying partial cargoes of bulk grain:- A ship not having on board a document of authorization issued in accordance with A 3 of this Code may be permitted to load bulk grain provided that:

- The total weight of the bulk grain shall not exceed one third of the deadweight of the ship.

- All filled compartments, trimmed, shall be fitted with centreline divisions extending, for the full length of such compartments, downwards from the underside of the deck or hatch covers to a distance below the deck line of at least one eighth of the maximum breadth of the compartment or 2.4 m, whichever is the greater, except that saucers constructed in accordance with A 14may be accepted in lieu of a centreline division in and beneath a hatchway except in the case of linseed and other seeds having similar properties.

- All hatches to filled compartments, trimmed, shall be closed and covers secured in place.

- All free grain surfaces in partly filled cargo space shall be trimmed level and secured in accordance with A 16, A 17 or A 18.

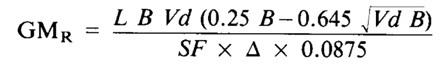

- Throughout the voyage the metacentric height after correction for the free surface effects of liquids in tanks shall be 0.3 m or that given by the following formula, whichever is the greater:

Where:

L = total combined length of all full compartments (metres)

B = moulded breadth of the vessel (metres)

SF = stowage factor (cubic metres per tonne)

Vd = calculated average void depth calculated in accordance with B 1 (metres – Note: not millimetres)

D = displacement (tonnes); and

6) The master demonstrates to the satisfaction of the Administration or the Contracting Government of the port of loading on behalf of the Administration that the ship in its proposed loaded condition will comply with the requirements of this section.

A ship without such a document shall not load grain until the master satisfies the Administration, or the Contracting Government of the port of loading on behalf of the Administration, that the ship will comply with the requirements of the International Grain Code in its proposed loaded condition.