Hazards associated with Coal:

- Spontaneous heating

- Emission of Methane

- Corrosion

- Liquefaction

Special precautions for handling Bulk Coal – IMSBC code guideline:-

Loading bulk coal: The IMO Code of Safe Practice for Solid Bulk Cargoes includes detailed recommendations for the safe loading and carriage of coal cargo. It states that coal may heat spontaneously and that some coals may be liable to self-heating which could lead to spontaneous combustion. The section ‘General requirements for all coals’ stresses the most important advice for the safe loading and carriage of coal:

Cargo temperature is to be monitored (not more than 40c deg), the methane content to be monitored (not excess of 10% of the LEL). In this respect, please be guided that your vessel is provided with the necessary instruments to calibrate.

The ship shall be kept upright during loading of this cargo. This cargo shall be so trimmed to the boundaries of the cargo space that the angle of the surface of the cargo with horizontal plane does not exceed 25 deg. This cargo shall be kept as dry as practicable. This cargo shall not be handled during precipitation. During handling of this cargo, all non-working hatches of the cargo spaces into which the cargo is loaded or to be loaded shall be closed.

Vessels shipping coal should at all times carry on board instruments for measuring methane, oxygen and carbon monoxide gas concentrations, so that the atmosphere within the cargo space can be monitored. The instrument should be regularly serviced and calibrated so that it can provide the crewmembers with reliable data about the atmosphere within the cargo space. Care needs to be exercised in interpreting methane measurements carried out in the low oxygen concentrations often found in unventilated cargo holds.

The catalytic sensors normally used to detect methane rely on the presence of sufficient oxygen for accurate measurement. This phenomenon does not affect the measurement of carbon monoxide or measurement of methane by infrared sensor. However, additional guidance should be sought from the manufacturer of the instrument.

An instrument required for measuring methane, oxygen and carbon monoxide concentrations should be fitted with an aspirator, flexible connection and a length of tubing, thus enabling a representative sample to be obtained from within the square of the hatch.

Stainless steel tubing approximately 0.5m in length and 6mm nominal internal diameter with an integral stainless steel threaded collar is often preferred. The collar is necessary to provide an adequate seal at the sampling point.

A suitable filter should be used to protect the instrument against the ingress of moisture as recommended by the manufacturer. The presence of even a small amount of moisture would compromise the accuracy of the measurement.

Avoid all unnecessary handling, even the removal of wet clothing. If handling is necessary, then it should be as gentle as possible. Enclose the survivor in a plastic bag or blankets or preferably both. It is important that the head, but not the face, is well covered. Place in a warm area with a temperature not exceeding 22øC. Never attempt to give any fluids by mouth to an unconscious casualty.

Bilge precautions: Bilge wells shall be clean, dry and covered as appropriate, to prevent ingress of the cargo.

Weather precautions: Unless the vessel is specially constructed, the Moisture content of the cargo shall be kept less that TML during voyage.

Stowage & segregation: This Cargo shall be separate from goods of classes 1,2,3,4,5 n IMDG

Ventilation: Following the special precautions in IMDG.

Hold cleanliness: Clean and Dry as relevant to the hazards of the cargo.

Special Precautions

- Coal emitting methane

- Self-heating coals

- Gravity-field self-unloading bulk carrier

-

Chief Mate Orals Function 1 FAQ Notes₹ 207.00

Chief Mate Orals Function 1 FAQ Notes₹ 207.00 -

2nd Mate (F.G.) & NCV (NWKO) – Volume 3 (Cargo)₹ 219.00

2nd Mate (F.G.) & NCV (NWKO) – Volume 3 (Cargo)₹ 219.00 -

Cargo Consolidated Notes for Phase 1 Chief Mate₹ 361.00

Cargo Consolidated Notes for Phase 1 Chief Mate₹ 361.00 -

Cargo Solved MMD Past Papers Phase 1 Chief MatePrice range: ₹ 244.00 through ₹ 576.00

Cargo Solved MMD Past Papers Phase 1 Chief MatePrice range: ₹ 244.00 through ₹ 576.00

Ventilation methods for bulk cargo against ship sweat or cargo sweat:-

Many cargo claims arise due to lack of ventilation of the cargo, particularly agricultural products. A common procedure for ventilating hatches at sea is to `crack’ them open.

Considerable care must be taken during this procedure as the ships hatch tops are not designed to be opened during any rolling motion. When such hatches are opened they must not be left in the jacked up position, but should be lowered onto the compression bars and locked into position.

Under no circumstances should the hatches be left open at night while on passage. A lack of, or improper, ventilation can lead to condensation (also known as sweating), which causes cargo deterioration. There are two types of sweat:

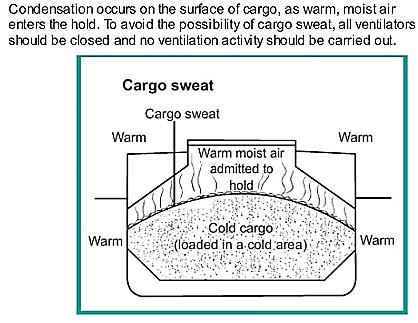

Cargo Sweat:

Condensation occurs on the surface of the cargo as warm, moist air enters the cargo hold containing a cold cargo. For example, if a cargo of steel is loaded in winter in the UK for discharge in Singapore, the temperature of the cargo will be low. If warm moist air is later introduced in the cargo hold, condensation takes place as soon as it comes into contact with cold cargo. To avoid the possibility of cargo sweat, all ventilators should be closed and no ventilation carried out. However, if the moisture content of the cargo is high, extraction of the moist air from within the cargo holds may be required.

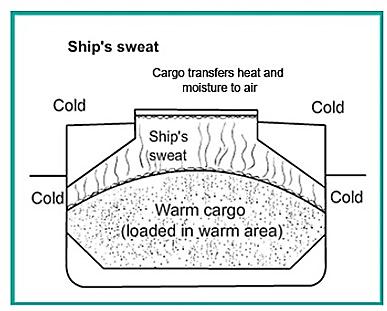

Ship Sweat:

This results when condensation occurs on the ship’s structure as the ship becomes colder moving from a hot to a cold climate. The warm moist air within the cargo compartment condenses as it comes into contact with the cold structure of the vessel. For ship sweat to occur, the dew point in the cargo hold must exceed the temperature of the ship’s structure. To eliminate ship sweat the cargo should be ventilated if the vessel is moving from a warm to a cold climate. Cargoes can be:

Hygroscopic: mainly agricultural products containing natural moisture. They may absorb, retain or release moisture, depending upon the surrounding atmosphere. Examples include grains. On a voyage from cold to hot region these type of cargo need no ventilation and from hot to cold region surface ventilation needed.

Non-Hygroscopic: solid cargoes. However, these cargoes are very likely to be damaged by cargo sweating. To avoid cargo damage no ventilation required

Air is said to be saturated if it can no longer absorb any moisture. If it is then cooled it will start to cause condensation. The temperature this occurs at is known as the dew point temperature.

To determine the amount of moisture in the air (the relative humidity), a wet and dry bulb thermometer is used in an instrument known as a `hygrometer’. It is important to ensure a flow of air across the two thermometers in a hygrometer to obtain correct readings. In a cargo hold where there is no air flow, a whirling hygrometer is used to measure the two temperatures. A table is then used to find the relative humidity at the time of observation. If proper ventilation procedures are not followed moisture damage is likely. Any shipper’s instructions should be complied with and the following factors considered:

Ensure that the shipper’s declaration contains sufficient information about the cargo, particularly moisture content, TML and ventilation requirements, particularly if the commodity is not normally carried or the areas of trade are uncommon:

- Claims for moisture damage to cargo can only be defended if supported by properly maintained documentation. It is critical that records of hold temperatures, humidity and durations of ventilation are maintained.

- The dew point temperature of the cargo hold and outside air should be compared. If the outside dew point temperature is lower or equal to that within the cargo hold, then ventilation should be continued. Since measurement of temperature in a cargo hold filled with bulk cargo may not always be possible, a comparison should be made between the temperature of cargo at the time of loading and the outside temperature. If the dry bulb temperature of the outside air is 3 degrees or more higher than the cargo temperature, continue ventilation.

- Ventilation not only serves to control sweating, it can control the gases or odours emitted from cargo.

- If seawater spray or rain enters the cargo holds, all ventilation should be stopped and times noted until conditions change to allow resumption of ventilation.

- Ventilation should be continued even at night if required.

- If circumstances allow there should be regular inspection of the cargo space for any signs of condensation, eg on the underside of the hatch access covers. If condensation is found, ventilation should be continued

- a record of cargo hold temperature and ventilation should be kept.