Preparations & Precautions before Loading a Large Dimension Cylindrical Shaped Heavy Lift on the Deck of a Cargo Ship:

Safe stowage and securing of portable tanks:-

- The provisions of Annex 2 of “Code of Safe Practice for Cargo Stowage and Securing” apply to a portable tank, which in the context of this annex, means a tank which is not permanently secured on board the vessel and has a capacity of more than 450 l and a shell fitted with external stabilizing members and items of service equipment and structural equipment necessary for the transport of liquids, solids or gases.

- These provisions do not apply to tanks intended for the transport of liquids, solids or gases having a capacity of 450 l or less.

Note: The capacity for portable tanks for gases is 1,000 l or more.

General provisions for portable tanks:-

- Portable tanks should be capable of being loaded and discharged without the need of removal of their structural equipment and be capable of being lifted onto and off the ship when loaded.

- The applicable requirements of the International Convention for Safe Containers, 1972, as amended, should be fulfilled by any tank- container which meets the definition of a container within the terms of that Convention. Additionally, the provisions of part 6 of the IMDG Code should be met when the tank will be used for the transport of dangerous goods.

- Portable tanks should not be offered for shipment in an ullage condition liable to produce an unacceptable hydraulic force due to surge within the tank.

- Portable tanks for the transport of dangerous goods should be certified in accordance with the provisions of the IMDG Code by the competent approval authority or a body authorized by that authority.

Portable tank arrangements:-

- The external stabilizing members of a portable tank may consist of skids or cradles and, in addition, the tank may be secured to a platform- based container. Alternatively, a tank may be fixed within a framework of ISO or non-ISO frame dimensions.

- Portable tank arrangements should include fittings for lifting and securing on board.

Note: All types of the aforementioned portable tanks may be carried on multipurpose ships but need special attention for lashing and securing on board.

Cargo information:-

- The master should be provided with at least the following information:

- Dimensions of the portable tank and commodity if non- dangerous and, if dangerous, the information required in accordance with the IMDG Code.

- the gross mass of the portable tank; and

- whether the portable tank is permanently secured onto a platform-based container or in a frame and whether securing points are provided.

Stowage:-

- The typical distribution of accelerations of the ship should be borne in mind in deciding whether the portable tank will be stowed on or under deck.

- Tanks should be stowed in the fore-and-aft direction on or under deck.

- Tanks should be stowed so that they do not extend over the ship’s side.

- Tanks should be stowed so as to permit safe access for personnel in the necessary operation of the ship.

- At no time should the tanks overstress the deck or hatches; the hatch covers should be so secured to the ship that tipping of the entire hatch cover is prevented.

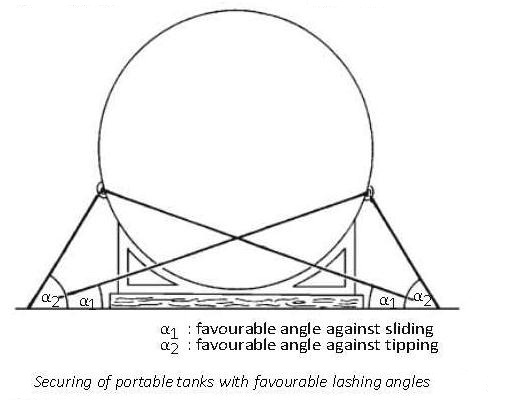

Securing against sliding and tipping:-

- Non-standardized portable tanks

- The securing devices on non-standardized p o r t a b l e tanks and on the ship should be arranged in such a way as to withstand the transverse and longitudinal forces, which may give rise to sliding and tipping. The lashing angles against sliding should not be higher than 258 and against tipping not lower than 458 to 608 (figure 3).

- Whenever necessary, timber should be used between the deck surface and the bottom structure of the portable tank in order to increase friction. This does not apply to tanks on wooden units or with similar bottom material having a high coefficient of friction.

- If stowage under deck is permitted, the stowage should be such that the portable nonstandardized tank can be landed directly on its place and bedding.

- Securing points on the tank should be of adequate strength and clearly marked.

Note: Securing points designed for road and rail transport may not be suitable for transport by sea.

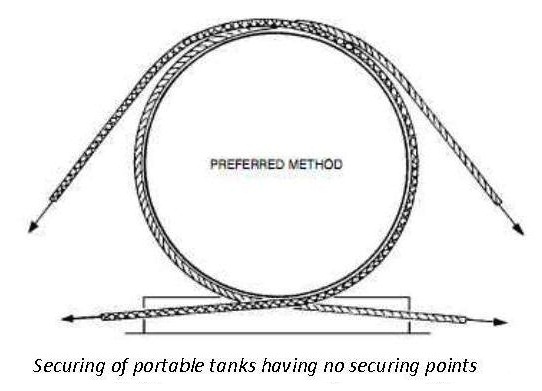

- Lashings attached to tanks without securing points should pass around the tank and both ends of the lashing should be secured to the same side of the tank.

- Sufficient securing devices should be arranged in such a way that each device takes its share of the load with an adequate factor of safety.

- The structural strength of the deck or hatch components should be taken into consideration when tanks are carried thereon and when locating and affixing the securing devices.

- Portable tanks should be secured in such a manner that no load is imposed on the tank or fittings in excess of those for which they have been designed.

- Standardized portable tanks (tank-containers):- Standardized portable tanks with ISO frame dimensions should be secured according to the system of lashing with which the ship is equipped, taking into consideration the height of the tank above the deck and the ullage in the tank.

- Maintenance of securing arrangements:-

- The integrity of the securing arrangements should be maintained throughout the voyage.

- Particular attention should be paid to the need for tight lashings, grips and clips to prevent weakening through chafing.

- Lashings should be regularly checked and retightened.

Care and Maintenance of a Crane Wire:-

Wires maintenance & how to avoid mechanical damage:-

Provided that the grooves in the sheaves are in good order and that the wire is allowed to run free and not be dragged over coamings, the crane wire should not suffer mechanical damage. The Duty Officer must always be on the lookout for bad practices by crane operators, and stop any abuse of the ship’s equipment. The Chief Officer must be informed immediately if such bad practices have been witnessed in order that an appropriate claim can be made.

Standard regulations dictate that a wire must be replaced when 10% of the visible strands are broken within a length of nineteen times the diameter. This is a fair guideline and is to be the worst condition into which the wire is allowed to fall, before replacing it. Before arrival at loading/discharging ports, the wires must be checked for broken strands, by sighting along the length of the wire in both directions. It is inexcusable for any vessel to arrive in port and suffer a failure of port/inspection due to a faulty wire. This must be discovered early enough to change the wire in time to commence cargo operations without delay to the vessel, and is the responsibility of the Chief Officer.

Wires -greasing – protection:- Apart from the mechanical stresses placed on crane wires during operation, the factors most affecting their working life are:-

- Weather Protection

- Lubrication

Regular application of good quality wire rope grease will fulfil both purposes. It is the responsibility of the Chief Officer to ensure that sufficient stocks of suitable grease are held on board.

Because most wire greasing will be done with the jibs in the stowed position, there are certain parts of each wire which will be less accessible. These are those parts of the hoist and luff wires which lie on a sheave, and those parts which lie inside the crane structure. Attention must be paid to the ends of the wires where they are secured, as this part of the wire is often very inaccessible and overlooked. It is essential that any extra time required, is taken to ensure adequate protection in this area.

There are no circumstances which can excuse a vessel arriving in port, where the deck cranes are to be used, with the wires in a dry condition. However, it must be remembered that, especially in very warm weather, that if the crane wires have been over greased it is possible that the grease may begin to run and drop onto the cargo. This must also be avoided as it may result in cargo damage claims.

Precautions for Heavy Lift Onboard:-

- Carry out a “Risk Assessment” prior to commencing the operation to ensure that all possible areas of hazard are taken account of and that all risks are at an acceptable, tolerable risk level.

- Ensure that the stability of the vessel is adequate to compensate for the anticipated angle of heel that be experienced when the load at the maximum angle of outreach.

- All free surface elements should be reduced or eliminated, if possible, to ensure a positive value of GM throughout the operation.

- Any additional rigging, such as “preventer backstays” should be secured as per the ships rigging plan.

- A full inspection of all guys, lifting tackles, blocks, shackles and wires should be conducted prior to commencing the lift by the officer-in-charge. All associated equipment should be found to be incorrect order with correct SWL shackles in position and all tackles must be seen to be overhauling.

- Allowance must be made for the weight lifted plus the purchase weight.

- End links ring or shackles to ride freely from whichever point they hang.

- While slinging, wood or other packings to be used to protect the sling from any sharp edges on the load and to prevent the sling from cutting into the load.

- Remove guard rails, if possible.

- Avoid shocks due to load slipping or sudden start.

- Men should be ordered to lift the gangway from the quayside and the ordered to positions of standby, to tend the vessels moorings at the fore and aft stations

- The ships fenders should be rigged to prevent ship contact with the quayside at the moment of heeling.

- Ensure that the deck area, where the weight is to be landed (when loading) is clear of obstructions and the deck plate is laid with timber barriers (heavy dunnage) to spread the weight of the load.

- The ships plans should be consulted to ensure that the limitations of the density plan and deck load capacity is not exceeded.

- Check that the winch drivers are experienced and competent and that all winches are placed into double gear to ensure slow moving operation.

- Release any barges or small boats moored to the shipside before commencing any heavy lift operation.

- Secure steadying lines to the load itself and to any saucer/collar connection fitment attached to the lifting hook.

- Inspect and confirm the lifting points of the load are attached to the load itself and not just secured to any protective casing.

- Ensure that the area is clear of all unnecessary personnel and that the winch drivers are in sight of a single controller.

- Set tight all power guys, and secure the lifting strops to the hook and load respectively.

- When all rigging is considered ready, the weight of the load should be taken to “float the weight clear of the quayside (loading).This vessel will cause the vessel to heel over as the full weight of the load becomes effective at the head of the derrick boom.

- Some lateral drag movement must be anticipated on the load and it is important that the line of plumb is not lost with the ship heeling over.

- Once the load is suspended from the derrick and the chief officer can check that the rigging of the equipment is satisfactory, then the control of the hoist operation can be passed to the hatch controlling foreman.

Assuming that all checks are in order, the chief officer would not normally intervene with the lifting operation being controlled by the hatch foreman, unless something untoward happened which would warrant intervention by the ship’s officer. This is strictly a case of too many cooks could spoil a safe loading operation.

NB: The main duties of the chief officer are to ensure that the vessel has adequate positive stability and this can be improved by filling DB water ballast tanks. Additionally, he should ensure that the derrick is rigged correctly and that all moving parts are operating in a smooth manner.

Precautions to be taken as a Chief Officer Before & During Loading of a Boiler Weighing 200 Tonnes:

A 200 ton boiler shall be categorized as a project cargo, which is defined as a cargo or equipment that may be large, heavy or out of gauge & requires specialized stowage, lifting & handling requirements, for safe shipment of such cargoes.

Precautions to be exercised while loading such project cargo are enumerated as below:

1) Such project cargoes are insured & the cargo insurers will stipulate certain conditions (a warranty) for the purpose of the insurance. If the cargo meets certain criteria then it is referred to as a critical items.

Critical items require special attention, during their loading, transportation & a careful assessment and detailed planning to carry such operation is required.

2) It is Masters responsibility to ensure that all cargo, whether it is safety stowed, properly secured & handled with care during loading & discharging operations and in accordance with the requirements of Charter Party.

The Charter Party may dictate specific responsibilities of the vessel owner, charterer and shipper, such as the specific responsibility for stowage, lashing and securing of cargo.

3) The rules of the vessel’s classification society, will also set out the requirements for maintenances of vessels, including equipment required for loading, stowage & securing of project cargoes. If these requirements are not followed, the vessels owners may be liable in the event of an incident.

4) The vessel’s Cargo Securing Manual guidelines should be referred to ensure the vessel suitability to carry such project cargo & securing arrangements for the same.

5) The Code of Safe Stowage CSS Code, 2003. should be referred in conjunction with the Cargo Securing Manual for safe stowage and securing recommended for a range of cargoes including project cargo.

6) The Intact Stability Criteria is specified in Res. A. 749 (18) should be confirmed by the Master, sufficient to permit & safe margin of positive stability throughout the loading operation & voyage.

Damaged stability criteria as set out in SOLAS Chp. II-I (MSC Circ.82) also need to be considered.

7) The shipper shall provide instructions for the safe and proper stowage and securing of the cargo. For more complicated shipments, particularly those for large heavy items a detailed “Transport Manual” or “Method of statement” should be provided which include:

- Management of project, responsibilities & key contacts.

- Details of cargo/ vessel.

- Vessel strength & stability requirements.

- Port details.

- Loading procedure.

- Stowage Requirements

- Voyage Planning & transshipment

- Discharge Procedures

8) A Marine Warranty Surveyor is appointed on behalf of the cargo insurance under writers who insures the shipment of cargo. In cases, where a warranty surveyor attends to approve loading & securing of cargo, a certificate approval (COA) or Letter of Approval is to be issued on satisfactory completion of operations, adhering to the standards of safe stowage & securing.

Definition of Lifting Appliances with context of ILO- 152 convention, 1979:-

The term Lifting Appliance covers all stationary or mobile cargo-handling appliances, including shore-based power-operated ramps, used on shore or on board ship for suspending, raising or lowering loads or moving them from one position to another while suspended or supported.