Procedure for Inspection Of Wire Rope:-

A visual and physical examination should take place at regular intervals. Under normal conditions of use, wire rope can be inspected every 3 months. If a broken wire is discovered, then it should be inspected more often. A thorough inspection is given below.

Externally

- Inspect termination of rope at the drum and other points.

- Inspect for broken wires.

- Inspect for corrosion.

- Inspect for deformation.

- Inspect for surface wear.

- Inspect for defective coiling.

- Inspect for deterioration due to snatch loading.

- Inspect lengths that run through blocks, particularly those which lie on the sheaves when the appliance is in the loaded condition.

Internally

Open the lay.

- Check internal lubrication.

- Degree of corrosion.

- Indentation caused by pressure of wear.

- Presence of broken wires.

An accurate log should be kept of inspection dates, rope condition, end for ending, replacement, etc.

Broken Wires: – Broken wires are usually a result of fatigue and wear.

Discard if:

Marine Order (part 32) “The total number of broken wires visible in a length of S.W.R. equal to 10 times it’s diameter should not exceed 5% of the total number of wires constituting the rope”.

Strand Distortion

Strand distortion is generally a result of damage caused by kinking, crushing, bad nips or other violent treatment. Commonly found in berthing hawsers, and ropes which have to be worked in adverse conditions.

Abrasion

Occurs both internally and externally.

Caused by:-

- Friction over sheaves, leads, sharp or rough objects

- Dirt, dust, grit lodging within strand wires.

Indicated by:-

- Deposits of fine brown powder between strands

- Flattening of internal surfaces of individual wire.

Corrosion

Generally caused by lack of lubrication. When wire rope is under tension, the fibre heart and cores are also compressed, releasing oil to overcome friction.

Maintenance of wire ropes:-

Uncoiling New Cordage

Below 48 mm the rope can be taken direct from the inside of the coil. This will maintain its protective wrapping. With right handed rope the coil should be stood on the end which will allow the rope to be taken off left handed from the inside.

Uncoiling the rope in the wrong direction will insert twist and increase the danger of kinking.

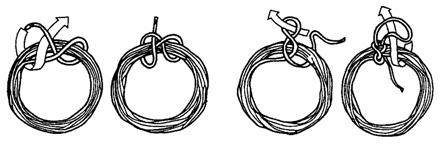

Coiling

Always coil ropes in the direction of Lay,

ie., Left hand (L.H.) lay anti-clockwise

Right hand (R.H.) lay clockwise

Two methods of finishing coils are shown in the above figure.

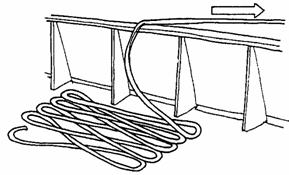

To avoid problems in paying out a rope, it should be flaked down, see Figure. This avoids it becoming tangled or kinked.

A fancy way to finish a rope is with a Flemish Coil. It SHOULD ONLY be used for tidiness and never when required to render quickly through a block, see Figure.

Before cutting the desired length of rope, whippings should be applied close to each side of the intended cut. Failure to observe this precaution can cause excessive unlaying of the rope.

Care and Maintenance

Chemicals: – Natural fibre rope is severely damaged by chemicals. Synthetic ropes are much more resistant.

Heat: – Excessive heat will melt synthetic ropes and make natural ropes dry and brittle.

Storage: – Store ropes in a well-ventilated dry atmosphere away from heat, strong sunlight and corrosive substances. Natural fibre rope will quickly rot if stowed away wet. Always dry out before storing. Keep loose coils OFF the deck.

Cleaning of Ropes:

If a rope has been used in mud, sand or grit, it should be cleaned thoroughly before being stored. To wash rope, hang it up in loose coils or flake it out on the deck and hose with fresh water.