Procedure for sampling of Iron Ore Fines:

Shippers are required, as per Section 4.3.3 of IMSBC, to establish procedures for ‘sampling, testing and controlling moisture content to ensure the moisture content is less than TML’. These procedures should be approved and their implementation checked by the competent authority of the port of loading. The master must be provided with the documentation issued by the competent authority confirming that the procedures have been approved prior to commencing loading.

Unfortunately there have been many instances where the information provided by the shipper has stated that the moisture content of the cargo has been within the TML but which cargo has later proven to be liable to liquefy.

This can come about through poor testing procedures (despite detailed advice as to the conduct of tests contained within the IMSBC Code), changes in circumstance since testing was carried out e.g. heavy rain (again the Code requires the shipper to retest in these circumstances but often shippers fail to do this), or through lack of understanding by shippers’ representatives of the potential dangers posed to the vessel by spurious figures.

As such, even where the certificate states that cargoes are safe to load, masters and their officers must always be vigilant in monitoring the condition of the cargo as it comes onboard. Different stockpiles of cargo can have different characteristics so vigilance throughout the duration of loading operations is necessary.

Should a dispute arise over the properties of the cargo to be loaded we recommend that Members consider appointing an independent surveyor/expert to assist the master. In such circumstances Members should contact the Association for advice.

Sampling and Testing of Cargo:-

Sampling and testing procedures for bulk cargoes that may liquefy should be carried out to international standards such as the test procedures described in Appendix 2 of the IMSBC Code.

-

2nd Mate (F.G.) & NCV (NWKO) – Volume 3 (Cargo)₹ 219.00

2nd Mate (F.G.) & NCV (NWKO) – Volume 3 (Cargo)₹ 219.00 -

Cargo Consolidated Notes for Phase 1 Chief Mate₹ 361.00

Cargo Consolidated Notes for Phase 1 Chief Mate₹ 361.00 -

Cargo Solved MMD Past Papers Phase 1 Chief MatePrice range: ₹ 244.00 through ₹ 576.00

Cargo Solved MMD Past Papers Phase 1 Chief MatePrice range: ₹ 244.00 through ₹ 576.00

Flow Moisture Point (FMP) and Transportable Moisture Limit (TML):

Flow Moisture Point – the maximum water content, expressed as a percentage, at which a sample of cargo will begin to lose shear strength. Cargoes with moisture content beyond FMP may be liable liquefy.

Transportable Moisture Limit – is defined as 90% of the FMP when used in conjunction with the Flow Table Test (FTT) and Penetration Test. The modified Proctor Fagerberg test method can be used to determine the TML of iron ore fines.

From the ship operators and master’s perspective the important figures for the laboratory to determine are the TML of a representative sample of the cargo to be loaded and its actual moisture content. It is a requirement of the International Convention for the Safety of Life at Sea (SOLAS) that the average moisture content of any type of granular cargo in any cargo space must not be higher than the TML.

In order to find the TML, the laboratory must first determine the FMP of the sample using one of the prescribed techniques.

For the Modified Proctor Fagerberg test there is no FMP, the vessel will only be provided with a TML.

Loading a cargo above, at or near its FMP represents an unacceptably high risk for vessels and for this reason a safety margin is allowed – this gives the TML.

After determining the FMP the moisture content of the cargo is obtained by drying samples of the cargo in accordance with Section 4.6.4 of the Code. If the moisture content of the cargo sampled is below the TML then, on the face of it the cargo should be safe to load. However, there is no way for the vessel’s operators or master to determine whether or not the sampling and testing procedures used by shippers are adequate and/or accurate.

Can Test:

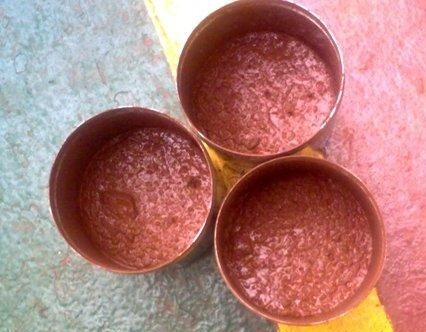

In order that the vessel can make its own assessment of the likelihood of the cargo to liquefy section 8 of the IMSBC Code describes a shipboard method known as the “can test”. This involves filling a small can with the material and repeatedly banging it on a hard surface.

The appearance of the material at the end of the test can be used to form an opinion regarding the suitability of the material for shipment. This test should not be a substitute for proper laboratory testing using an appropriate methodology. However, if can tests carried out on a cargo presented for loading indicate a propensity for liquefaction, this is a major warning sign that the cargo as a whole may be unsafe for carriage.

Expert advice should then be sought. Where shippers present significant amounts of material that fails the can test (a failed can test with an iron ore fines cargo is pictured), this is an indication that the cargo as a whole may be unsafe, and that any certification to the contrary may be flawed. It should also be borne in mind that a negative result from the can test (i.e. no free moisture or fluid condition is seen) does not necessarily mean that the cargo is safe for shipment.

Liquefaction Process:

- In fine grained moisture laden cargo the spaces between cargo grains are filled with both air and water. Whilst at sea the cargo is subject to forces due to the vibration and rolling of the vessel.

- These forces cause the inter-grain spaces to contract. The water in the spaces between grains is subject to a compressive force but as it is a liquid it cannot be compressed.

- This has the effect of reducing the inter-grain frictional force that holds the cargo in a solid state. Where enough moisture is present the reduction in inter-grain friction due to the ship’s motion and vibration can be sufficient to cause the cargo flow like a liquid i.e. to liquefy.

Hazards associated with carriage of Iron Ore Fines:-

- No special Hazards.

- This cargo is non-combustible or has a low fire-risk.

- Iron ore cargoes may affect magnetic compasses.