GUIDELINES FOR EMERGENCY TOWING ARRANGEMENTS ON TANKERS:

1. PURPOSE:

1.2 The present Guidelines are intended to provide standards for the design and construction of emergency towing arrangements which Administrations are recommended to implement.

1.3 For existing tankers fitted with the emergency towing arrangements in accordance with resolution A.535 (13), the existing towing arrangements forward of the ship may be retained, but the towing arrangements aft of the ship should be upgraded to comply with the requirements of the present Guidelines.

2. REQUIREMENTS FOR THE ARRANGEMENTS AND COMPONENTS:

2.1 General:

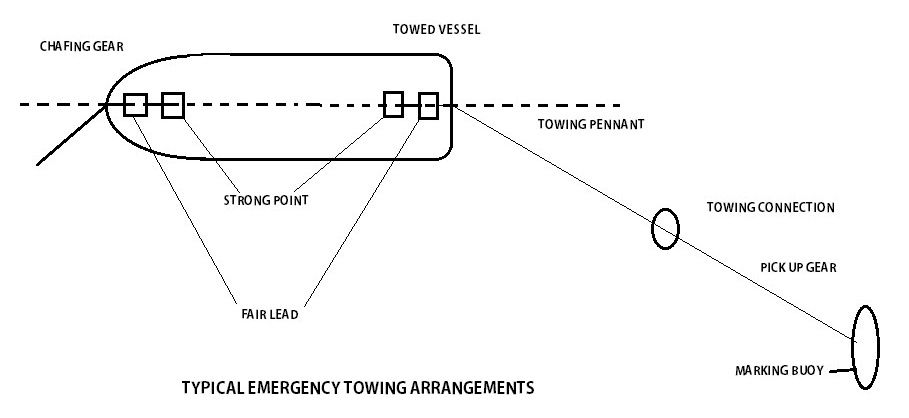

The emergency towing arrangements should be so designed as to facilitate salvage and emergency towing operations on tankers primarily to reduce the risk of pollution. The arrangements should at all times be capable of rapid deployment in the absence of main power on the ship to be towed and easy connection to the towing vessel. Figure shows arrangements which may be used as reference.

2.2 Towing Components:

| Forward of Ship* | Aft of Ship* | Strength Requirements | |

| Pick-up gear | Optional | Yes | — |

| Towing Pennant | Optional | Yes | Yes |

| Chafing gear | Yes | Depending on design | Yes |

| Fairlead | Yes | Yes | Yes |

| Strongpoint | Yes | Yes | Yes |

| Rolling Pedestal | Yes | Depending on design | — |

The major components of the towing arrangements should consist of the following:

2.3 Strength of the towing components:

2.3.1 Towing components as specified in 2.2 for strength should have a working strength of at least 1,000 kN for tankers of 20,000 tonnes deadweight and over but less than 50,000 tonnes deadweight and at least 2,000 kN for tankers of 50,000 tonnes deadweight and over(working strength is defined as one half ultimate strength). The strength should be sufficient for all relevant angles of towline, i.e. up to 90° from the ship’s centerline to port and starboard and 30° vertical downwards.

2.3.2 Other components should have a working strength sufficient to withstand the load to which such components may be subjected during the towing operation.

2.4 Length of towing pennant:

The towing pennant should have a length of at least twice the lightest seagoing ballast freeboard at the fairlead plus 50 m.

2.5 Location of strongpoint and fairlead:

The bow and stern strongpoint and fairleads should be located so as to facilitate towing from either side of the bow or stern and minimize the stress on the towing system.

2.6 Strongpoint:

The inboard end fastening should be a stopper or bracket or other fitting of equivalent strength. The strongpoint can be designed integral with the fairlead.

2.7 Fairleads:

2.7.1 Size:

Fairleads should have an opening large enough to pass the largest portion of the chafing gear, towing pennant or towing line.

2.7.2 Geometry:

The fairlead should give adequate support for the towing pennant during towing operation which means bending 90°to port and to starboard side and 30°vertical downwards. The vending ratio (towing pennant bearing surface diameter to towing pennant diameter should be not less than 7 to 1.)

2.7.3 Vertical location:

The fairlead should be located as close as possible to the deck and, in any case, in such a position that the chafing chain is approximately parallel to the deck when it is under strain between the strongpoint and the fairlead.

2.8 Chafing Chain:

Different solutions on design of chafing gear can be used. If a chafing chain is to be used, it should have the following characteristics:

2.8.1 Type

The chafing chain should be stud link chain.

2.8.2 Length

The chafing chain should be long enough to ensure that the towing pennant remains outside the fairlead during the towing operation. A chain extending from the strongpoint to a point at least 3 m beyond the fairlead should meet this criterion.

2.8.3 Connecting limits

One end of the chafing chain should be suitable for connection to the strongpoint. The other end should be fitted with a standard pear-shaped open link allowing connection to a standard bow shackle.

2.8.4 Stowage

The chafing chain should be stowed in such a way that it can be rapidly connected to the strongpoint.

2.9 Towing connection

The towing pennant should have a hard eye-formed termination allowing connection to a standard bow shackle.

2.10 Prototype test

Designs of emergency towing arrangements in accordance with these Guidelines should be prototype tested to the satisfaction of the Administration.

3. READY AVAILABILITY OF TOWING ARRANGEMENTS:

3.1 To facilitate approval of such equipment and to ensure rapid deployment, emergency towing arrangements should comply with the following criteria:

3.1.1 The aft emergency towing arrangement should be pre-rigged and be capable of being deployed in a controlled manner in harbour conditions in not more than 15 min.

3.1.2 The pick-up gear for the aft towing pennant should be designed at least for manual operation by one person taking into account the absence of power and the potential for adverse environmental conditions that may prevail during such emergency towing operations. The pick-up gear should be protected against the weather and other adverse conditions that may prevail.

3.1.3 The forward emergency towing arrangement should be capable of being deployed in harbour conditions in not more than 1 h.

3.1.4 The forward emergency towing arrangement should be designed at least with a means of securing a towline to the chafing gear using a suitably positioned pedestal toller to facilitate connection of the towing pennant.

3.1.5 Forward emergency towing arrangements which comply with the requirements for aft emergency towing arrangements may be accepted.

3.1.6 All emergency towing arrangements should be clearly marked to facilitate safe and effective use even in darkness and poor visibility.

3.2 All emergency towing components should be inspected by ship personnel at regular intervals and maintained in good working order.

Tractor Tug:

Tractor Tugs: The design of tractor tugs is unlike that of conventional tugs. The propulsion units are fully turning controllable pitch blades, able to give thrust in any direction and act as steering units or azimuthing fixed or controllable pitched propellers. The propulsion units are placed far ahead of the towing point, close to the pivot point thereby producing a large turning momentum. This potentially gives a poor steering performance, which is overcome by fitting a large centreline skeg. Their general characteristics are:

- Full power available in all directions

- Quick response to engine movements.

- Very maneuverable, especially in tight sea space.

- Reduced risk of girting / girding.

- Reduced maneuverability if towing from forward at higher speeds.

- Reduced directional stability, particularly in open waters.

- Reduced bollard pull per kilowatt output.

- Relatively deeper in draught therefore increased risk of bottom damage from grounding.

- Increased training required for tug masters.

Tow Plan:

Planning and preparation before a Tow commences might include:

- Assessing the size and type of vessels or barges to be towed and any limitations of the tow.

- Confirmation that the tug is of suitable; size, manning, sea-keeping, horse power (HP) and bollard pull (BP).

- Tow wire and towing equipment is suitable for the planned tow.

- Route to be taken and passage planned, including safe transit times (day/night transits), times when passing through narrows, under bridges or areas of high traffic density, tight bends in rivers and adjacent river berths.

- Noting: and areas of reduced depth, tidal limitations and currents expected during the voyage.

- A list of bridges with maximum and minimum height; tide height for each arch to be passed under showing the bridge’s maximum air-drafts.

- Weather forecasts to include outlook for at least 48 hours.

- Confirmation of sufficient fuel, water, spares on board.

- Navigational information and warnings.

- Recommended speeds to comply with river regulations.

- Connection and disconnection arrangements.

- Stability of the tug and towed unit.

- Emergency contingency plans.

Preparations on board the Tug:

It is essential that checks should be completed on board the tug and vessel or barge to be towed, which should include:

- All water / weathertight openings are securely closed with signs indicating that they should remain closed for the duration of the voyage. It is a reality that tugs have capsized as a result of doors and ports being left open when in difficulty, e.g. girting. Down flooding is a real danger to small tugs.

- Life-saving and fire-fighting appliances must always be operational.

- Navigational equipment, wheelhouse whistles, horns, shapes for day signals and communication gear are fully operational.

- All critical machinery prior to commencing a towing operation should be confirmed as operational – this would include; main engine, steering gear and towing equipment (winches, wires) etc.

- All personnel are fully familiar with the intended towage plan and their responsibilities.

- Any change of fuel and ballast to the tug and/or tow have been fully calculated and the crew are aware of any factors of concern.

Checks on board the towed vessel or barge:

The tow should not proceed until a satisfactory inspection of the tow has been carried out by a competent party.

Checks should include:

- Condition of the towing arrangements

- Condition of the anchoring equipment if fitted. If not fitted some authorities require a temporary anchor to be supplied of an adequate weight.

- Condition of tow including an inspection of the peaks and buoyancy spaces to check for water ingress.

- Watertight integrity of the unit to be towed; obvious signs of damage, especially in the hull and deck plating. Hatchways, ventilators, doors, scuttles, manholes and other openings are closed and sea valves shut.

- Fore and aft drafts, appropriate freeboard for the voyage and no evidence of a list. Generally a slight trim by the stern ensures that the tow is laterally stable when towed.

- Air draft of the tow, appropriate for the voyage and bridge transits.

- Power is available for navigation lights.

- Safe method of boarding available (portable or fixed rungs).

- Emergency towline rigged.

- Life-saving and fire-fighting appliances are in good condition and in the regulatory number required.

- Cargo, whether it is bulk cargo (within the holds), containers or break bulk cargo can shift causing the barge to capsize and sink and therefore stowage and securing arrangements must be verified as adequate for the intended voyage prior to departure.

- Some bulk cargoes pose a serious hazard, including spoil and certain ore cargoes which are liable to liquefaction e.g. spoil cargoes can contain a high amount of moisture which can assume a liquid state in a seaway and can cause the barge to lose stability, list and even capsize.

- Reference should be made to the IMO International Maritime Solid Bulk Cargoes (IMSBC Code). When it is suspected that cargoes with high moisture content have been loaded onto a barge advice should be sought.

- If cargo is liable to move e.g. vehicles and timber, the lashing arrangements and sea fastenings should be inspected.